Chemical Safety

Chemical Hygiene Plan

The Chemical Hygiene Plan describes the safe and proper use, handling practices, and procedures to be followed by personnel working in University laboratories necessary to protect them from potential health and physical hazards presented by chemicals used in the workplace, and to keep chemical exposures below specified limits. The laboratory safety requirements apply to all faculty, staff, and students engaged in the laboratory use of hazardous chemicals.

Chemical Labeling

All Chemical Containers must be Labeled with either the original label or a new label. Includes Transferred Chemicals and Solutions New Labels must include:

- Chemical Name

- Hazard(s)

- Date

- Manufacturer or Lab Owner

Classification and Storage of Hazardous Chemicals

Safe handling of chemicals is dependent on their properties and safe handling appropriate to those properties. Chemicals should be separated by the Hazard Classes shown below with secondary containment as required.

For additional guidance refer to the Stand Operating Procedure (SOP) for General Guidelines for Chemical Storage.

- Inorganic mineral acids

- Solvents

- Bases

- Oxidizers

- Poisons

- Explosives

Working with Chemicals

- Know your protocol / execute meticulously

- Plan your need for protective equipment

- Know your chemicals and potential hazards

- Date material when received and at disposal

- Use smallest quantity of material

- Consider safer substitutes

- Wear personnel protective equipment

- Whenever possible, use a fume hood

- Be alert for hazards, pay attention to your work

Chemical Inventory Management

The Environmental Health and Safety Assistant (EHSA) is an environmental and safety database used for regulatory compliance. It is a LSU requirement that every lab maintain an electronic chemical inventory. The EHSA provides a strong inventory program for maintaining chemical inventory. The program is web based. Your PAWS ID and password allow access to the system. If you have difficulty accessing the system, please contact EHS and we can adjust the internal security settings so that you should be able to see information relating to your research group.

EHS is requires that lab personnel utilize the Inventory Section to maintain their chemical inventory by adding and deleting chemicals as required. All incoming chemicals must be bar coded and the bar codes are provided by EHS. A hard copy of the chemical inventory in the lab can be printed from the reports section. The permit worker section can be used to add and delete personnel as needed. The training section shows the required and completed on-line training for each lab worker. The waste pickup section must be used to submit waste request. Door placards for your lab can be printed from the Administrative Reports section.

EHSA Training

The EHS web site provides the EHS User Handbook that provide instructions for operation of the system.

Chemical Inventory Guidelines

LSU requires that lab chemicals be barcoded and entered in the Environmental Health & Safety Assistant (EHSA).

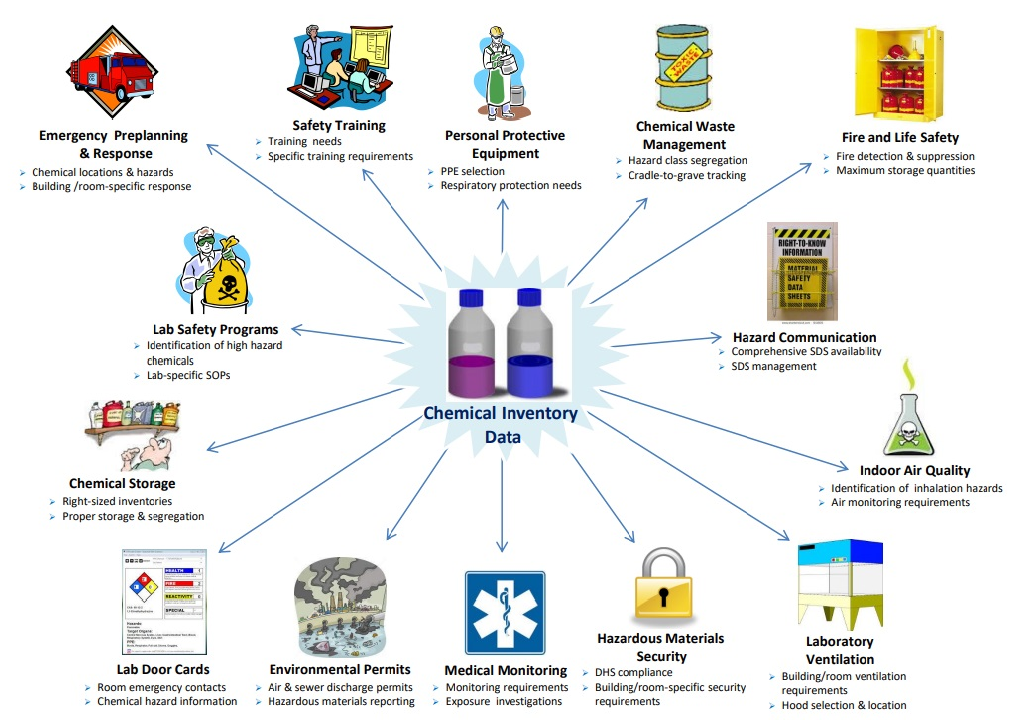

Chemical Inventory Value

A current chemical inventory supports all aspects of chemical safety which includes:

Emergency Preplanning & Response

- Chemical locations & hazards.

- Building/ room-specific response.

Fire and life Safety

- Fire detection & suppression

- Maximum storage quantities

Lab Door cards:

- Room emergency contacts

- Chemical hazard information

Hazard Communications:

- Comprehensive SOS availablity

- SDS management

Hazard Communications:

- Comprehensive SOS availablity

- SDS management

Lab Safety Programs:

- Identification of high hazard chemicals.

- Lab-specific SOPs.

Environmental Permits:

- Air & sewer discharge permits.

- Hazardous materials reporting.

Indoor Air Quality:

- Identification of inhalation hazards

- Air monitoring requirements

Personal Protective Equipment

- PPE selection

- Respiratory protection needs

Lab Safety

- Risk assessment, appropriate storage, personnel training, MSDS access, shelf-life expirations, CHP, SOP documents.

Medical Monitoring:

- Monitoring requirements

- Exposure investigations

Laboratory Ventilations:

- Building/room ventilations requirements

- Hood selection & location

Chemical Waste Management

- Hazard class segregation

- Cradle-to-grave tracking

Value Added

- Principal Investigator: inventory management, budget management, accountability, chemical sharing options.

- Allows researchers to search for chemicals throughout the campus.

Hazardous Materials Security:

- DHS Compliance

- Building/room-specific security requirements

Chemical storage:

- Right-sized inventories

- Proper storage and segregation

Regulatory Drivers

- EPA: 2004 Supplemental Environmental Project – RCRA Enforcement Action

- LDEQ: Air and water discharge permits; Community Right-To-Know.

- State Fire Marshall: chemical use, hazard classes; building and room quantities.

- OSHA: Hazard Communication; Lab Standard.

- Homeland Security: inventory and accountability of materials, security/theft.

Inventory Methodology

All the labs under an individual PI will be done as a group.

- A lab walk through will be conducted by EHS to meet with PI to address their special needs and concerns.

- The chemical inventory will be scheduled with PI.

- Inventory data will be captured via an internet interface using the EHSA.

- Inventory teams will conduct the inventory at each lab using lap-top computers.

- All containers being inventoried will be handled and returned to their original location.

- All containers will be bar-coded to facilitate cradle-to-grave tracking.

- Simple seven-digit number with linear bar code provided by EHS

- All containers will be listed as full, regardless of actual volume:

- Provides conservative estimates on compliance with maximum allowable limits.

- Allows rapid acquisition of inventory information by the Inventory team.

- A person representing the lab is requested to be present to assist the inventory team with location of items and point out any special handling requirements (e.g., temperature, light sensitive items). If PI’s have any special handling concerns and prefer self implementation, the inventory team will be happy to coordinate such activities.

- PI’s (and/or designated alternates) will be provided read-only access to their own inventory immediately upon completion of their inventory. Full access will be provided upon system training.

Will Inventory

- All chemicals and chemical products obtained from commercial sources (Sigma, VWR, etc.) (Including purchased mixtures)

- Long term chemical storage containers with clearly identifiable hand-written labels.

- Paints

- Aerosols

- Refrigerants

- Lubricants, fuels, and oils

- Scintillation fluid

- Compressed, liquefied gasses

Will not inventory

- Chemical reagent solutions prepared in the lab or workplace

- Short term chemical storage containers with handwritten labels

- Chemicals obtained directly from laboratory synthesis

- Household chemicals

- Enzymes (any form)

- Microbiological growth media

- Microorganisms

- DNA/RNA kits

- Regulated radioactive materials

- Water, any grade (for example HPLC, distilled/deionized, etc.)

- Chromatographic column material (GC, LC)

- Unregulated radioactive materials (Uranium, Thorium compounds) (Contact Radiation Safety)

Labs can inventory additional materials and adjust container amounts if they wish (when full privileges are available).

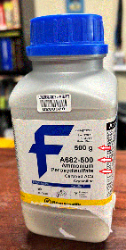

Data Entry

- Chemical Name

- PI

- Lab

- Storage Location

- CAS Number

- Units

- Amount

- Vender Name

- Catalog number

Refer to EHSA User Handbook for the additional instructions on how to enter chemicals into the EHSA database

An excellent source of the above information is the original chemical label.

General Bar-Coding

- Place the bar code in a clear area so that chemical information is not covered up.

- On small bottles, put the bar code label in a place where you can still read the chemical information.

- You can make a tape flag that shows the bar code label.

- Use clear tape to cover any chemical bottle that will be stored in a refrigerator or freezer.

- Tape over and label that has become loose.